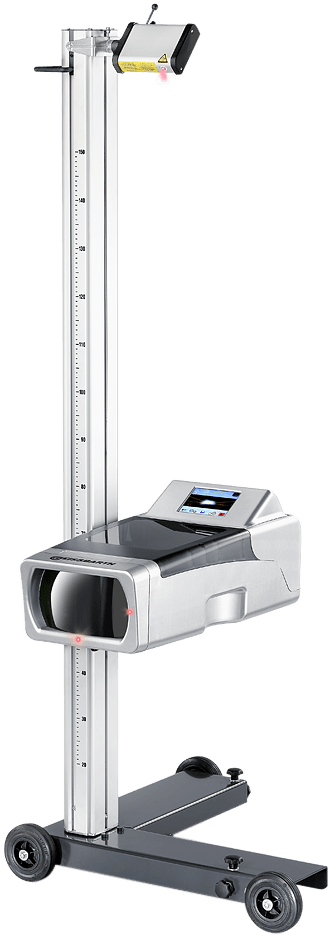

MLD 815

$5,236.00

Hubwerks Headlight testing device MLD 815

Digital Headlight Measure & Adjusting tool

SKU: 1692104323

Data Sheet BB ADAS

Technical Data

German Road Traffic Type-Approval Law StVZO § 29 general-inspection headlight-test directive: MLD 815 can be calibrated according to the legal requirements.

TÜV certificate in line with StVZO § 50 – TPN 10010 6935: MLD 815 is TÜV-certified by prototype technical release examination in accordance with the directives for testing headlight adjustment/test equipment (German Road Traffic Type-Approval Law StVZO §50 paragraph 5).

- The alignment (leveling) of the MLD 815 on the testing bay corresponds to the latest requirements.

- Two-dimensional spirit level for horizontal leveling of the optical box

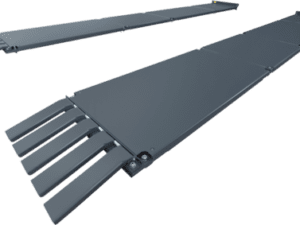

- Levelable 3-Wheel base system fitting for all common rail systems

- Levelable rail system for above and inground installation (3 m) as an optionally available accessory

- Digital headlight testing with MLD 815: intelligent, fast, and precise

- Cross- and alignment laser for precise positioning

- For all light sources (Xenon, Bi-Xenon, LED, Bi-LED, Halogen) and glare-free high-beam systems (Dynamic Light Assist – DLA, Matrix, ILS Ford)

- All types of vehicles (passenger cars, trucks, motorcycles)

- All types of headlights (main headlights, fog lamps, auxiliary lamps)

- CMOS camera for real-time digital image processing

- Built-in printer

- Measurement results in real-time

- Comparison between measured and limit values and unambiguous red/green evaluation

- The precise definition of the cut-off line without disrupting the blue fringe

- Digital LCD color display (5.7″) with 262,000 colors

- Touch-screen function (operation with gloves is possible)

- Intuitive and simple user guidance

- Visual and acoustic signals support the measurement procedure

- Menu featuring 7 languages

- The operating panel can be rotated by 180° for different areas of application (e.g. for general inspections or for the adjustment at the workshop)

- Independent operation thanks to the battery – Storage battery Alignment laser: 3 x Mignon AA 1.5 V

- Measuring height (optical center): 24 – 145 cm

- Measured values: Horizontal and vertical deviation (pitch angle), intensity, roll angle, yaw angle

- Digital precision: +/- 1 cm on a 10-meter measuring distance

- Reliable check and adjustment of permanent high beams (e.g. Dynamic Light Assist – DLA, Matrix Beam, etc.)

MLD 815 assists the user with intelligent headlamps:

- Mechanical adjustment of the vertical cut-off line (e.g. DLA, ILS)

- The position of the cut-off line read out by means of the MLD 815 software – with an accuracy level based on angular minutes (e.g. bei Matrix Beam)

Note: To adjust the glare-free high beam, an OBD diagnostic device is also required

Note: For the accurate and reliable adjustment of the glare-free high beam (vertical cut-off-line), Beissbarth recommends an exactly leveled vehicle surface and a rail system.

| Test Results via WLAN on PC | Test results via WLAN with quick and aptly arranged results on the PC • Optional: visualization on the workshop computer |

|---|---|

| Specifications | • Operating temperature 5 – 45 °C |

Reviews

There are no reviews yet.